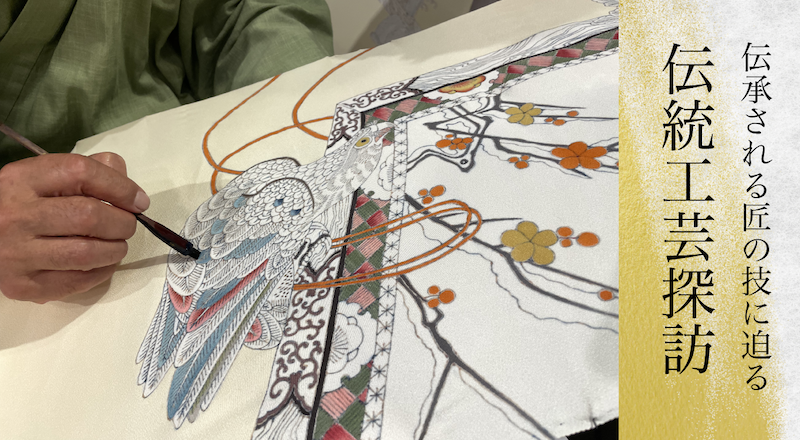

Exquisite Designs Woven on

Jacquard Looms with Masterful Precision

From a Raincoat Weaving House to a Textile Artisan Atelier

with Unwavering Dedication to Yarn, Structure, and Weave

Facing the Sea of Japan, Yamagata Prefecture is known for its high humidity and heavy snowfall in mountainous areas. These unique climate conditions once made Yonezawa a hub for weaving kimono raincoats. At its peak, over 40 weaving houses specialized in these garments—but today, only one remains: Sashime Orimono. We spoke with the fourth-generation successor, Mr. Sato.

Sashime Orimono was founded in 1924 (Taisho 13) by Mr. Sato’s great-grandmother, Ms. Shime Sato. It was remarkable at the time for a woman to lead a weaving house during the Taisho era. In 2000, the atelier registered its brand name “Iohataori”, inspired by the legendary garment “Iohatakoromo”, said to have been woven by the celestial weaver princess in the Tanabata myth. The name reflects their enduring commitment to crafting textiles with the same care and imagination as that mythical, beautiful robe.

Sashime Orimono has a long history as a weaving house specializing in kimono raincoats, once widely known for their elegant satin-weave pieces made with ultra-fine silk threads. During the height of traditional raincoat fashion, colors like vermilion and deep crimson were most common, often adorned with vertical or geometric patterns—designs that are now cherished as quintessentially Showa retro. Amidst this trend, Sashime Orimono distinguished itself by crafting rain-and-shine compatible kimono coats, kimono fabric, and obi, all woven on jacquard looms with refined, original motifs that stood apart for their beauty and innovation.

What makes Sashime Orimono truly exceptional is its commitment to pre-dyed silk yarns and the use of jacquard weaving techniques to create intricately detailed patterns. These traditional jacquard looms are entirely analog and demand the highest level of skill from the weaver. In an era where many weaving houses now rely on digital technologies and computer-generated patterns, Sashime Orimono continues to rely on mongami (punch cards) to operate their looms. For particularly complex designs, they may use over 2,000 cards—yet they remain committed to this time-honored method, prioritizing the structural ingenuity of the weave over convenience.

Tenpyo Nishiki is 4,000 Threads of Astonishing Density

Lightweight elegance for all seasons

One of the signature creations of Sashime Orimono is a rain-and-shine compatible coat fabric called Tenpyo Nishiki. Despite its exceptionally high thread density, each bolt weighs only around 500 grams. This remarkable balance of strength and lightness is achieved through the use of a weaving structure that employs silk filaments finer than human hair—for both warp and weft. The warp alone consists of approximately 4,000 silk threads, skillfully arranged and densely woven to enhance the fabric’s natural water resistance. Compared to Oshima Tsumugi, known for its durability in rain—while typical Oshima Tsumugi features around 1,200 to 1,400 warp threads per width unit, known as “maru-ki,” Tenpyo Nishiki achieves an extraordinary 4,000—showcasing an unparalleled density.

Thanks to this ultra-high density, the fabric blocks both wind and rain. It is often tailored as a single-layered coat suitable for spring, autumn, and even winter. The refined aesthetic of the coat also makes it ideal for sudden weather changes—if the rain stops and the sun comes out, it can still be worn confidently as a chic outer layer.True to its name, Tenpyo Nishiki takes inspiration from the elegant motifs found in the Shosoin Treasures, skillfully woven using the natural sheen of top-quality silk yarns. This refined finish makes the fabric versatile enough to layer not only over casual komon kimono, but also over visiting wear (houmongi) and even formal tomesode, adding a dignified presence to any ensemble.

“We paid close attention to creating a design that stands apart from conventional raincoats, but more than anything, we focused on comfort and ease of use,” says Mr. Sato.“Because we use extremely fine silk threads for both warp and weft, the fabric remains thin and lightweight, allowing the garment to be folded compactly even in full-length tailoring. It also has excellent shape retention—meaning it resists wrinkles even after being folded for long periods.Now, we’re applying this technique to create new pieces like kimono and obi.”

Pushing the Boundaries of Weaving:

Edo Komon Expressed in the Loom by Iohataori

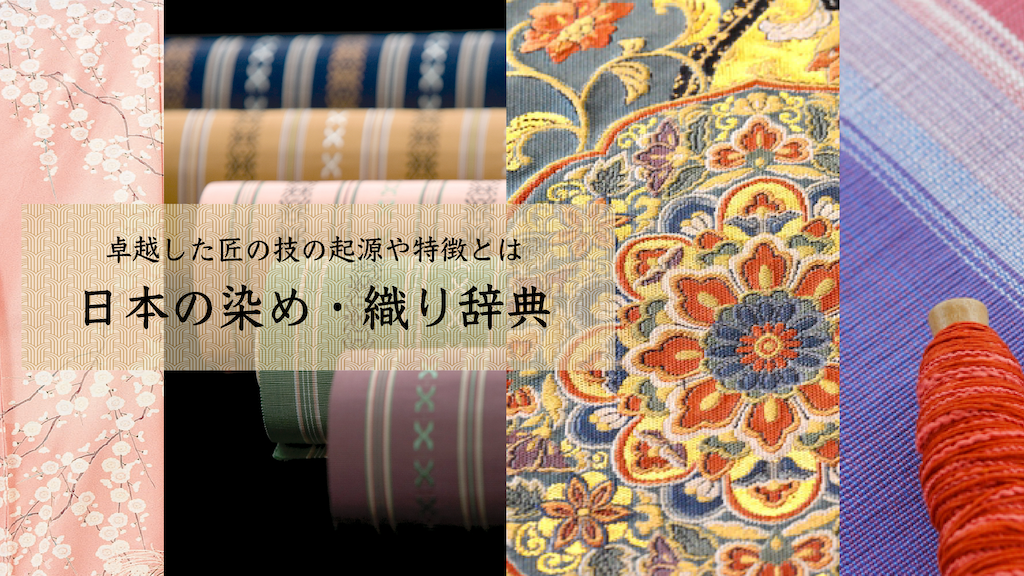

Edo Komon is traditionally known as a dyeing technique in which tiny, evenly spaced patterns are applied using stencils. From a distance, the fabric appears almost solid-colored, with a refined texture that reveals itself upon closer look. In this photo, you can see the Same Komon (sharkskin pattern), one of the classic motifs of Edo Komon, recreated through weaving.

In fact, this is not dyed but woven.The advanced technique of using ultra-fine threads is not limited to coats—it is also applied to kimono.Each piece is crafted with approximately 4,000 warp threads—three times the count typically used in standard-width tsumugi—allowing for the intricate expression of delicate patterns through highly complex mon-ori (figured weaving) techniques.

The weft threads are made from Sashime Orimono’s original hard-twisted silk yarn, spun with more than double the twist of the warp.Although it is a woven kimono fabric, this gives it an unexpectedly supple texture.The threads are so elastic that they stretch and contract when pulled, providing a natural resilience that resists wrinkling.This elasticity, combined with strong resistance to moisture, also prevents shrinkage—making it both practical and luxurious.

A Summer Kimono Designed for Long, Hot Seasons

Breathable comfort with lightweight, innovative silk

With the growing impact of climate change, including global warming, the traditional kimono calendar is gradually evolving. Outside of formal settings like tea ceremonies, it is now encouraged to choose garments based on the temperature rather than seasonal formality. It was in this context that “Natsukinu” was born—a summer kimono designed to be worn comfortably from early spring to late autumn, whenever the air begins to feel warm.

“As temperatures now reach 30°C even before midsummer, we needed something breathable for the early summer season,” says Mr. Sato, gently unfolding an airy bolt of sheer fabric. Its texture is light and crisp, and while translucent when viewed on its own, it becomes modest and non-transparent when layered with a juban undergarment.

“Ro(vertical-line sheer silk) and sha(open-weave silk) are typically considered midsummer fabrics, but Natsukinu was created to extend the season of enjoyment,” he explains.The secret lies in the yarn. By varying the twisting technique, the yarn gains a soft unevenness that gently touches the skin, creating a breathable, dry-to-the-touch texture that feels refreshingly smooth even in high humidity.

In addition to Natsukinu, Sashime Orimono has developed Usukinu, a feather-light haori fabric suitable for all but the coldest winter days.While monsha(a sheer silk weave featuring decorative patterns) is the mainstream choice for summer coats, this fabric takes a bolder approach—embracing the challenge of weaving large plain areas with a subtle twist in the warp, creating an understated yet sophisticated accent.

Carrying Tradition Forward:

Embracing Innovation in Weaving

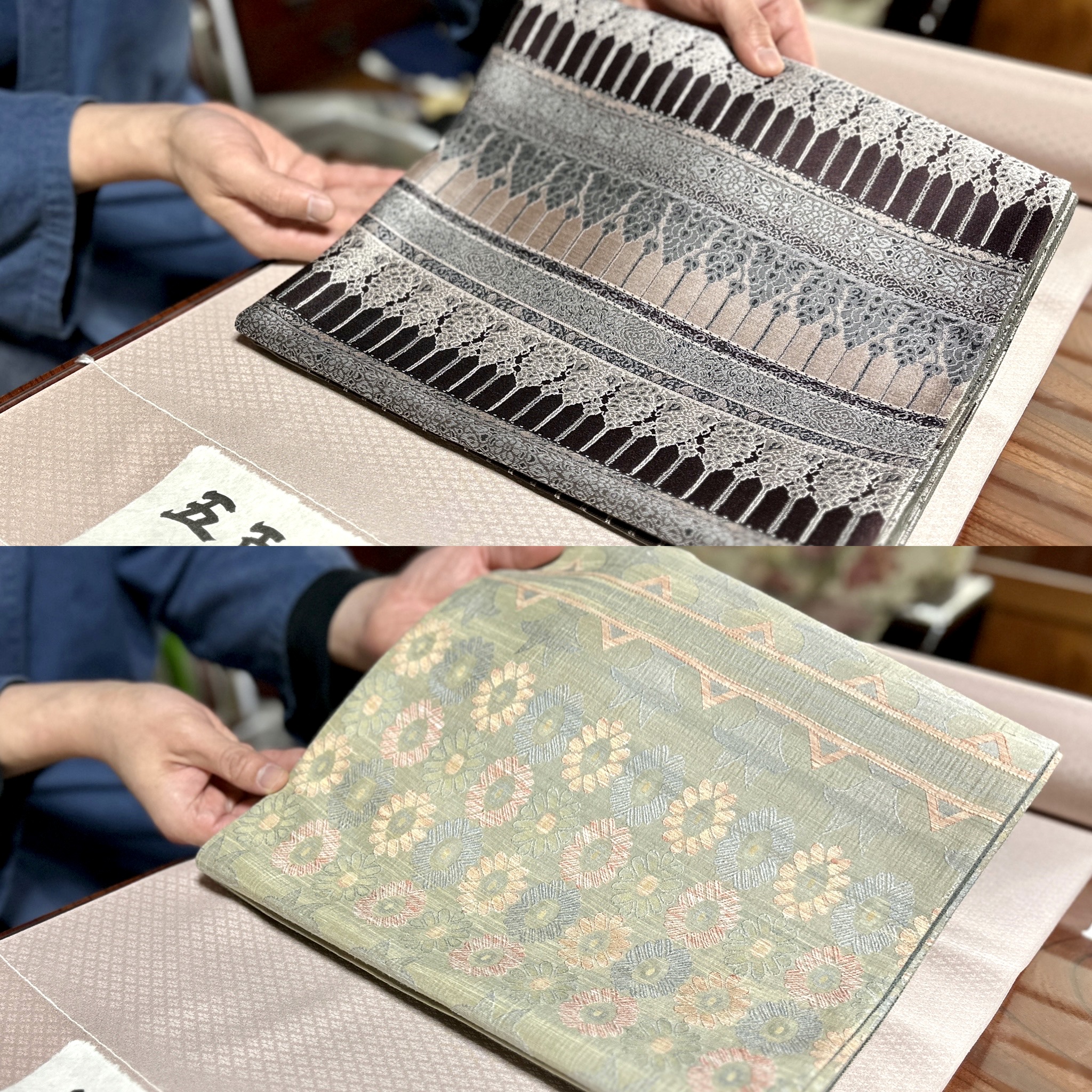

Sashime Orimono continues to evolve by applying time-honored techniques to create textiles suited to modern needs. Their obi sashes are particularly renowned—some are woven with 3,000 warp threads, showcasing luminous sarasa patterns that bring out the silk’s natural sheen. Others feature a warmer, softer texture using hand-spun mawata silk for the weft, expressing traditional motifs like ichigo-nishiki with a uniquely rich yarn structure. The lining fabrics are also woven in-house using matching threads, ensuring a seamless feel and exceptional comfort when worn.

Mr. Sato is currently working on a new summer obi that features a sha (open-weave) structure, perfect for wearing in the height of summer. While the loom setup for weaving summer obi had already been developed, he is now in the process of selecting suitable threads and refining the weaving technique.

“When I wove the first trial piece, I felt the weft wasn’t packed tightly enough. So I increased the density and used much thicker weft threads. The texture turned out beautifully, but the result was a bit too heavy,” he shares. “Now I’m reconsidering the balance and continuing prototypes to bring it closer to the ideal I have in mind.”

At the heart of Mr. Sato’s continuous pursuit lies a simple yet powerful wish — to create garments, obi, and coats that offer true comfort and joy to the wearer. Just as the celestial weaver princess (Orihime) is said to have woven beautiful robes with heartfelt care across the Milky Way, Mr. Sato and his team too continue to weave exquisite textiles with sincerity and skill, hoping to bring delight to those who wear them.

See Also : The Textile Encyclopedia / Yonezawa-ori & Yonezawa-tsumugi (Yamagata Prefecture)”

See Also : “Exploring the Allure of Yonezawa-ori Vol.1 / Nitta”

Sashime Orimono

2-1-9 Honcho, Yonezawa-shi, Yamagata Prefecture

TEL:0238-23-0788