A design inspired by the sparkling whitecaps of Amami’s deep blue sea. We visited his workshop to hear the story behind this captivating creation and its future potential.

In This Article:

- Textile artist Mr. Sachio Kizuki and his creations.

- Delicate patterns created through intricate warp and weft kasuri.

- The unique charm of his original “Shiranami Oshima”.

- A refined elegance distinct from traditional mud-dyed black.

- Contemporary designs that highlight local craftsmanship.

- Showcasing the diverse expressions of Oshima-tsumugi.

Shiranami Oshima is Unique Interpretation of

Amami’s Sea, Woven in Light and Waves

Amami Oshima is blessed with untouched natural beauty, and its vivid blue sea is one of its greatest treasures. The sea sparkles under the sun, shimmers with the evening glow, and reflects the moonlight in quiet silver waves. Shiranami Oshima captures this ever-changing beauty in woven form. Using only weft kasuri (discontinuous weft ikat), wave-like patterns emerge across the surface of the cloth, expressing the rhythmic rise and fall of the sea. This design is the result of Amamiya’s original approach, and is unlike any traditional Oshima Tsumugi produced before. We visited Mr. Sachio Kizuki — head of the weaving house Amamiya and the artist behind this work — to learn how this remarkable textile was born.

Over 45 Years in the World of Oshima-tsumugi

From Childhood to Sales Expert

Mr. Sachio Kizuki, the creator of Shiranami Oshima, is not only a textile artist but also a seasoned sales professional who has represented the finest Oshima Tsumugi fabrics from across Amami Oshima. For over four decades, he has introduced these works to kimono enthusiasts nationwide through department store events, including Takashimaya’s popular “Japan Traditional Crafts Exhibition,” where he represents Kagoshima annually. Spending nearly 70% of the year off-island, Mr. Kizuki has been deeply involved in promoting Oshima-tsumugi—but what inspired him to begin weaving himself?

“When the COVID-19 pandemic hit, my sales work came to a halt,” Mr. Kizuki recalls. “I began wondering what I could do—and decided to finally make use of the unused kasuri threads stored at Ama-Biya and try weaving Oshima-tsumugi myself.”

It didn’t take long before he was able to weave a full kimono. The reason: he had been surrounded by Oshima-tsumugi since childhood.

“My family ran a weaving house called Kizuki Orimono—my mother was the weaver, and my brother handled the shimebata (binding loom). As a child, the weaving studio was my playground. I’d get scolded for climbing on the looms, earn pocket money by winding threads, and help my brother apply starch to the warp threads.”

After graduating from high school, Mr. Kizuki trained at an Oshima-tsumugi workshop, where he learned processing techniques such as surikomi (dye rubbing). However, he left after a year and began working at a car company. It wasn’t until the age of 25—following the passing of his mother—that he felt compelled to return to his roots. Encouraged by his older brother, he entered the kimono industry and began working at a kimono boutique. Since then, he has spent 45 years promoting Oshima Tsumugi across Japan.

Breathing New Life into

Unused Threads with a Unique Vision

Among the materials left untouched at Ama-Biya were kasuri threads originally prepared for a design that had won an award in a local competition. While the warp threads had deteriorated over time, the weft threads were still in good condition. This inspired Mr. Kizuki to create a new piece using just the weft threads.

“It was easier to weave since I didn’t have to align the warp and weft,” he explains. “And when I looked at the design, I thought—what if I wove this pattern with only the weft? It might create an Oshima Tsumugi that resembles the white waves of the sea. I had a feeling it would become something entirely new.”

Mr. Kizuki was confident that his creation would resonate with customers. Years of firsthand interaction at kimono events had taught him exactly what enthusiasts were seeking. The more passionate a customer was about Oshima-tsumugi, the more they welcomed designs unlike anything they had seen before. Using indigo kasuri threads, he added irregular horizontal stripes to give Shiranami Oshima a modern flair.

The very first piece he completed was displayed at an exhibition—and sold immediately. The customer, delighted by the unconventional pattern, said, “It’s such a unique design. I love it.” Although Mr. Kizuki had sold Oshima-tsumugi for decades, it was the first time a piece he had personally woven was purchased. The emotional impact was unlike anything he had experienced before, solidifying his resolve to continue creating Shiranami Oshima.

Creating a New Kind of Oshima-tsumugi

That Customers Truly Want

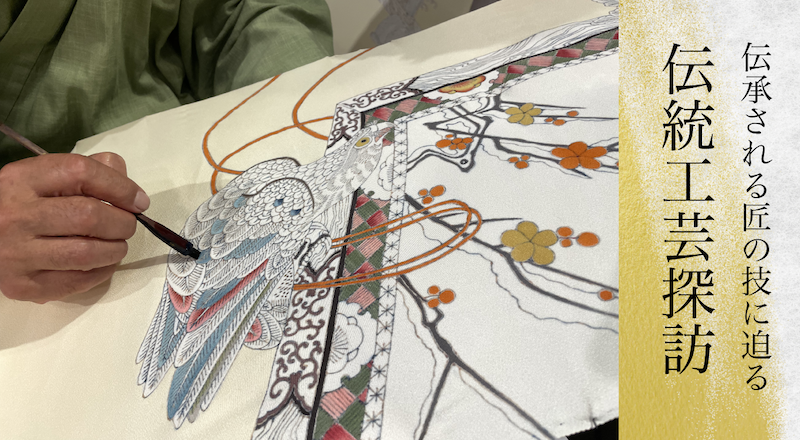

Mr. Kizuki’s studio houses two looms, both gifted to him by his sister-in-law. When we observed his weaving process, we saw him gently pressing the weft into place with his fingernails, carefully aligning the kasuri patterns with the design sheet placed underneath the warp. Every movement reflected his deep attention to detail—each thread woven with precision and intent to create something never before seen in Oshima Tsumugi.

“I learned to press the weft threads with my fingernails just by watching my sister-in-law weave,” Mr. Kizuki explains. “Now, I’m planning to incorporate kasuri patterns into the warp threads as well. Last year, I completed a shimebata (kasuri-binding loom) by myself. I’ve already prepared the threads—mud-dyed, wrapped in kasuri-mushiro mats, and wound onto boards, ready for future use.”

What he aims to create next is Ichigen-Gasuri—a traditional kasuri pattern formed using two warp and two weft threads. While ichigen-gasuri used to be the standard for authentic Amami Oshima Tsumugi, most weavers today use katasu-gasuri, which employs one kasuri warp thread and three plain weft threads. With katasu, only one warp thread needs to be shifted every few centimeters, making it more efficient for matching patterns. As a result, nearly all Oshima Tsumugi produced today is katasu-gasuri. “Precisely because it’s rarely made now,” he says, “I believe bringing back ichigen-gasuri has real value.”

“One of Amamiya’s greatest strengths,” Mr. Kizuki notes, “is that I can explain the story behind each piece directly to customers at the sales floor. When they understand the process, they buy with confidence—which gives me the freedom to keep creating.”

With decades of experience in both sales and production, Mr. Kizuki understands better than anyone what a “never-before-seen Oshima Tsumugi” truly means. As he continues to engage directly with customers, his innovative vision will no doubt expand the possibilities of authentic Amami Oshima-tsumugi.

See Also : The Textile Encyclopedia | Amami Oshima-tsumugi (Kagoshima Prefecture)

____________________________________

Weaving House Amamiya

21-16 Kasuga-cho, Naze, Amami City, Kagoshima Prefecture

TEL:+81-90-3309-6479

__________________________________

Text & Interview by Miki Shirasu