Carrying Forward a Legacy

That Once Captivated Shoguns

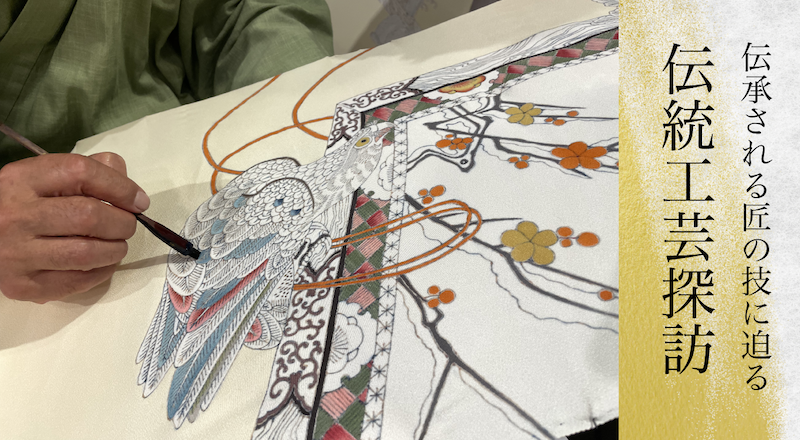

A Nishijin Atelier Pursuing Refined Beauty through Omeshi Weaving

In the Edo period, Omeshi — an elegant woven textile favored by Shogun Tokugawa Ienari — was considered a fabric of the highest prestige. Based in Kyoto’s Nishijin district, “Shinryusha” continues this noble tradition, fusing time-honored techniques with contemporary sensibilities to create exquisitely refined omeshi. Led by a proprietress and powered by a team of skilled women, Shinryusha brings to life a timeless aesthetic — the crystallization of beauty that transcends eras.

In This Article:

・The history of Shinryusha and its dedication to Omeshi.

・The fusion of traditional motifs with contemporary design.

・The craftsmanship behind tightly twisted “Omeshi-nuki” weft threads.

・Inherited color sensibilities and dyeing techniques.

・Refined processing by the only specialized factory in Nishijin.

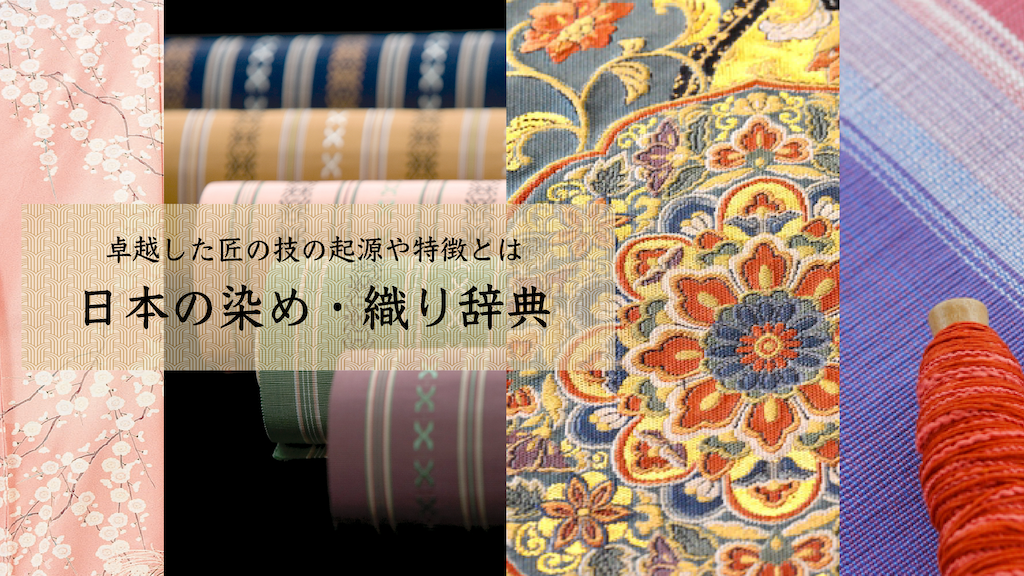

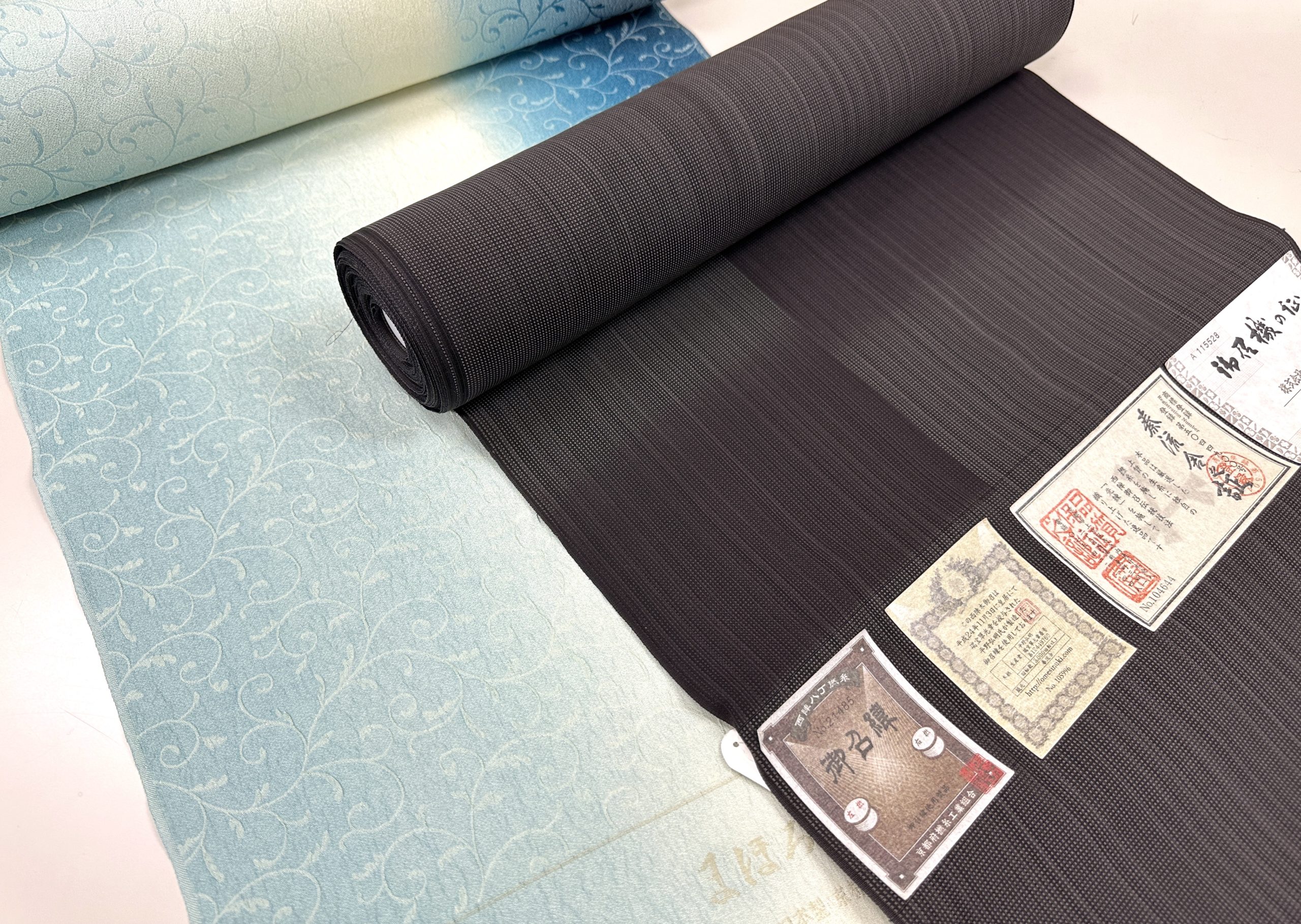

Woven with finely twisted “Omeshi-nuki” weft yarns, Nishijin Omeshi features a distinctive crimped texture. Once cherished by Tokugawa Ienari, a shogun of the late Edo period known for fostering vibrant merchant culture, Omeshi was named after garments worn by nobility. Today, it remains one of the most luxurious yarn-dyed textiles. In this feature, we explore the refined world of Nishijin Omeshi through a visit to Kyoto’s Shinryusha, where tradition meets modern beauty.

Blending Traditional Motifs with Modern Sensibilities

Exquisite Omeshi Born from Masterful Artisanship

Renowned for its refined designs expressed through intricate weaving techniques, Shinyusha has earned a devoted following. In Nishijin, where most weaving houses are led by men, it is Ms. Junko Nonaka—the proprietress—who oversees everything from design to final production. A native of Kyoto’s Gion district, she entered the world of weaving upon marriage and now serves as the company’s president. With a team composed of 80% women, this dynamic group creates Omeshi garments that are both delicately elegant and irresistibly luxurious once worn.

At Shinryusha, a new theme is chosen each year to guide the creation of their latest works. According to Ms. Nonaka, “Women are naturally drawn to stories. That’s why we place great importance on naming each theme in a way that conveys the world behind the design.”

For example, the Autumn/Winter 2022 theme was “Crystal”. Drawing inspiration from nature’s forms—plants, ice, and minerals—the designs expressed the beauty found in organic geometry. The theme also symbolized the crystallization of artisan skill, as each Omeshi Kimono is the result of more than 20 intricate steps.To embody this concept of “Crystal,” they developed a new fabric which holds a subtle, refined luster. Using ultra-fine twisted threads and a specially textured original yarn, they wove a richly shaded base cloth. Onto this, shimmering threads were used to create intricate woven patterns, resulting in a textile that truly represents the pinnacle of refined craftsmanship.

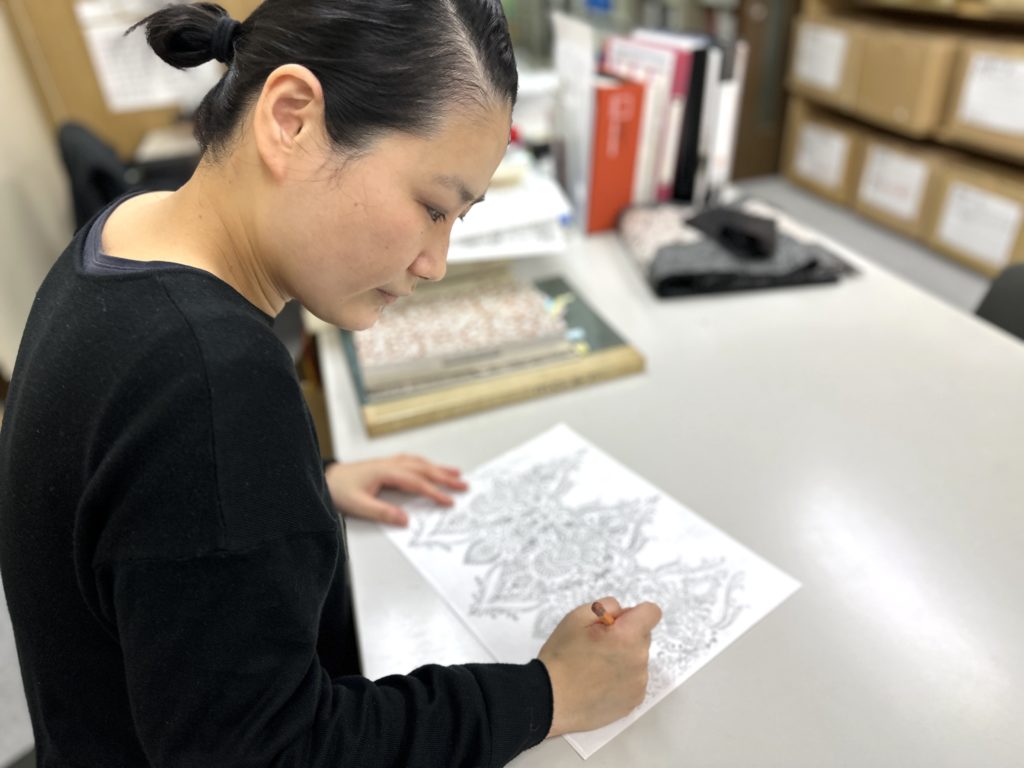

At the time of our visit in 2023, Shinryusha was working on a new collection inspired by European lace. The textile designer, Ms. Haruna Nakai, carefully balances traditional Japanese motifs with contemporary trends and the evolving needs of wearers. For each new project, she designs patterns based on the chosen theme while thoughtfully considering the type of loom, thread varieties, and weave structures best suited to the concept.

Durability Beyond Thread and Weave

A Timeless Palette Passed Down Through Three Generations

“What defines Shinryusha is that our Omeshi can be worn across three generations,” says Ms. Nonaka. This enduring appeal lies not only in the fabric’s durability, but also in its carefully considered color palette.

“We make sure the base colors aren’t overly bold, so that a Kimono bought in one’s 20s can still be worn comfortably in one’s 60s. We choose refined, urban tones that blend naturally with city life. At the same time, we incorporate subtle touches of vivid hues into the weft threads to reflect current trends without compromising timelessness.” This thoughtful balance makes Shinryusha’s Omeshi easy to coordinate and pair with different Obi, allowing a 30-year-old daughter and her 60-year-old mother to share the same Kimono simply by changing the styling obi. This intergenerational flexibility is at the heart of Shinryusha’s philosophy.

Omeshi Weft Yarn Refined to Perfection

at Nishijin’s Only Specialized Processing Facility

The quality of Omeshi fabric hinges on the excellence of its Omeshi-nuki—the highly twisted weft yarn. Compared to standard threads, the production of this yarn involves significantly more steps, and the resulting texture depends on the precision of each one. First, in the shita-yori (initial twisting), ultra-fine raw silk threads are aligned and twisted to achieve the desired thickness. Then, the itoneri (degumming) process removes sericin from the thread surface. Next, in the itozome (dyeing) process, the highly twisted yarn is carefully dyed to ensure even color throughout. The yarn is then coated with starch in the noritsuke (starching) stage, ensuring the glue penetrates to the core. Finally, in the hon-yori (main twisting) stage, an hatcho-nenshi-ki (a traditional twisting machine) is used to apply approximately 3,000 twists per meter. Each of these intricate steps is handled by master artisans—specialists in their respective fields—who collaborate as a team to achieve the exceptional quality demanded by Shinryusha. Together, they create a truly extraordinary yarn worthy of being called the soul of Omeshi.

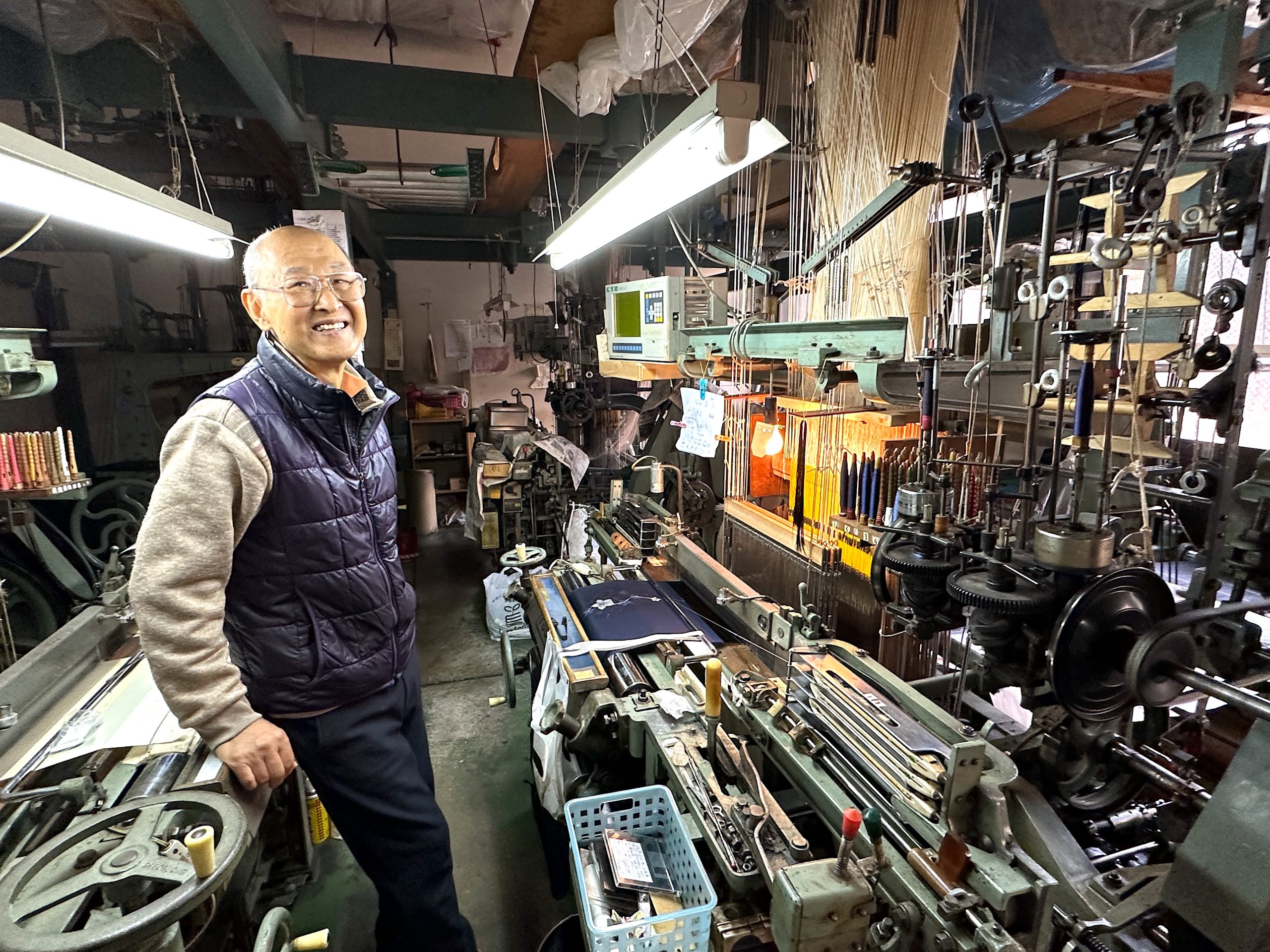

As part of this feature, we visited Kobayashi Nensen Factory, a company with over 100 years of history and the only specialized silk degumming (seiren) facility in the Nishijin area. President Mr. Akio Kobayashi kindly explained part of the production process, which involves removing sericin from the silk and giving the threads a soft, voluminous finish. Shinryusha provides highly detailed instructions regarding the degree of degumming required. During our visit, we were shown a side-by-side comparison of raw silk threads, partially degummed threads, and Shinryusha’s signature Omeshi-nuki yarn—carefully treated to create greater loft and softness. The difference in texture was clearly felt, revealing just how essential this stage is in achieving the refined quality of Shinryusha’s Omeshi.

“Shinryusha is highly particular about the feel of the finished textile,” says Mr. Kobayashi. “They give specific instructions according to each piece’s intended purpose, including requests like ‘finish it with this degree of firmness.’ In the case of their signature Omeshi, they choose not to degum the yarn, but instead to puff it up. This allows the glue applied in the next step to penetrate more easily. When the yarn is later twisted tightly, the glue helps protect the threads and prevents slippage. After weaving, during the yunoshi (steaming) process, the glue dissolves and the yarn’s built-in torsion causes the cloth to shrink, giving rise to Omeshi’s signature textured creases, or shibo.”

Mr. Kobayashi demonstrated the final stage of the process—using a metal rod to smooth bundles of thread. The once wavy silk quickly transformed, gaining both shine and alignment with each motion.

Masterful Weaving that Sustains

Nishijin Omeshi

Our next visit was to the workshop of Mr. Fusao Nakamoto, a master weaver who specializes in handling tightly twisted yarns. Now in his 70s, Mr. Nakamoto has dedicated his life to Nishijin weaving since graduating from high school. Due to the difficulty of handling these kyonen-shi (strongly twisted threads), many artisans avoid working with them. Yet Mr. Nakamoto patiently weaves full kimono bolt lengths of 13 meters—an increasingly rare skill. Because the yarns are natural fibers, they react to subtle shifts in temperature and humidity. Mr. Nakamoto constantly monitors these changes and adjusts the loom tension with counterweights to maintain consistency in the weave. The weights must be neither too heavy nor too light. With his finely tuned sensibilities, he maintains the delicate balance of tension and tension-release, producing exceptionally high-quality woven fabric with quiet precision.

“Omeshi weaving is time-consuming, so I constantly check to ensure there are no issues with the threads or the loom,” says Mr. Nakamoto. “Repair technicians for these looms are aging, and one day we might face problems that simply can’t be fixed anymore.”

He recalls a time when the sound of looms rang vibrantly throughout the Nishijin district. Now, with the number of operating looms dwindling, the area has grown noticeably quiet. While many weaving houses have closed over the years, Mr. Nakamoto continues to uphold the legacy inherited from his father, supporting Shinryusha’s creative endeavors from behind the scenes.

“Shinryusha sometimes brings me difficult weaving requests,” he says with a chuckle. “At first, I hesitate, but when they insist, I find myself wanting to make it happen. That’s the Nishijin spirit—responding with loyalty and pride.”

Timeless Elegance Woven into Every Thread

Exploring the Evolving Potential of Omeshi

The history of Nishijin textiles stretches back as far as the 5th or 6th century. As one of Japan’s most revered silk weaving traditions, it has evolved with the times while preserving its deep cultural roots. At Shinryusha, the art of Omeshi weaving is both inherited and reimagined—marrying time-honored craftsmanship with contemporary sensibilities and technical innovation.

Ms. Nonaka shared her thoughts on this pursuit “Just as fashion history tells us, there was once a time when women wore corsets or layered twelve-fold robes. But as women’s social status has risen, clothing has become lighter. When I first married into this family forty years ago, a single roll of kimono fabric weighed about 900 grams. Today, that weight has dropped below 700 grams. To make fabric lighter, some reduce the number of warp threads or use finer yarns—but that weakens the structure. What we value most in our kimono-making is how gracefully the garment follows the body, with a soft, elegant drape. To achieve that, we pay close attention to how we create the threads, balance the warp and weft, and control the density of the weave. Our specialty is Omeshi that feels both substantial and supple—textiles that gently embrace the body while maintaining strength and form.”

Shinryusha’s exquisite Omeshi embodies a timeless elegance—unaffected by trends—through refined design and subtle, sophisticated color palettes. At its heart lies the discerning aesthetic of its proprietress, and a spirit of continuous innovation alongside master artisans. This unwavering pursuit of beauty is what sets Shinryusha apart and continues to earn it loyal admiration.

__________________________________

Shinryusha

Shin-Inokuma Higashimachi, Kamigyo Ward, Kyoto

● Product Inquiries

Select Shop Yuzuki Kyoto Main Store

701 Kamishichiken, 702 Shinsei-cho, Imadegawa-dori, Nishinotoin, Kamigyo-ku, Kyoto, Japan

__________________________________