京友禅

Pronunciation: Kyo-yuzen

Production area: Kyoto City, Uji City, Kameoka City, Joyo City, Muko City, Kyoto Prefecture

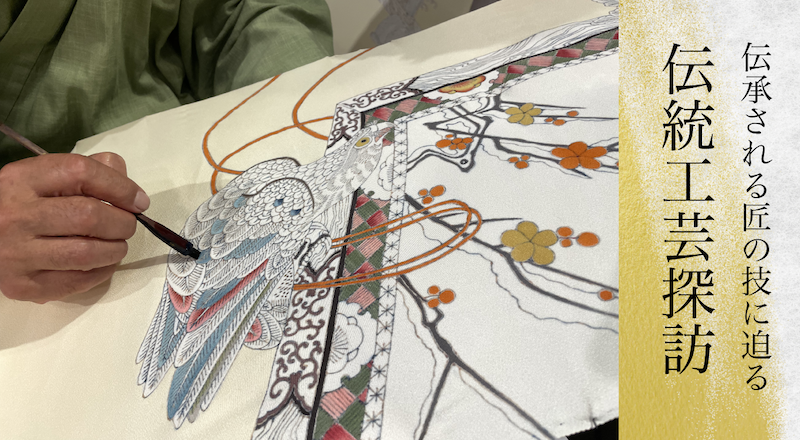

Kyo-Yuzen is one of Japan’s three great Yuzen dyeing traditions, along with Kaga-Yuzen and Tokyo-Yuzen. It is distinguished by elegant multicolored designs enhanced with gold and silver leaf or embroidery. Although dyeing techniques were introduced to Japan as early as the 8th century, Kyo-Yuzen was established between 1688 and 1703 by Miyazaki Yuzensai, a fan painter in Kyoto. The name “Yuzen” derives from him.

Yuzen dyeing, with its vivid colors and intricate, painting-like patterns, flourished during the mid-Edo period and gained popularity nationwide. In the Meiji era, the introduction of chemical dyes with brighter tones expanded the palette, and the master artisan Hirose Jisuke developed “Utsushi-Yuzen,” the forerunner of stencil-dyed Yuzen (Kata-Yuzen), which allowed for mass production. Today, the creation of Kyo-Yuzen involves as many as 14 highly specialized processes, carried out through a sophisticated division of labor among artisans.

京友禅の工程

1. Design planning

The artisan sketches the design layout, balancing motifs and colors, while also selecting the base fabric.

2. Draft drawing

Using aobana liquid extracted from dayflower petals, the artisan draws light outlines on the white fabric, then reinforces details with a darker indigo liquid.

3. Itome-gomu (rubber resist lines)

Rubber paste is applied along the outlines to prevent dyes from bleeding during painting. The paste is squeezed from a tube made of washi stiffened with persimmon tannin.

4. Fushi-nori (resist coating)

To protect pattern areas from ground dyeing, paste is evenly applied within the outlined sections, then sprinkled with rice powder (hikiko) to fix it.

5. Hikizome (brush dyeing)

The fabric is dyed with brushes, either evenly or in gradations.

9. Steaming(again)

The fabric is steamed at around 100°C for 20–50 minutes to set the dyes and enhance colors.

10. Washing (again)

Excess dye, paste, and chemicals are thoroughly washed out.

8. Hand-painting (Tessashi Yuzen)

Using brushes, the artisan hand-paints motifs with delicate attention to color and expression.

9. Steaming(again)

Another steaming process sets the applied colors.

10. Washing (again)

The fabric is carefully washed to remove all remaining paste and excess dye.

11. Kin-sai (gold decoration)

Gold leaf is adhered to the fabric for additional brilliance.

12. Hand embroidery

Silk, gold, and silver threads are embroidered using techniques known as “Kyo-nui,” adding depth and luxury.