In this feature, we visit Mr. Kazuto Kanai of Kanai Kogei, founded in 1958, to learn how the signature lustrous black color of Oshima-tsumugi is brought to life through this extraordinary process that connects craftsmanship with nature.

In This Article:

- Mud-Dyeing Mastery Unique to Amami.

- Techi Tree and Mud: The Black of Oshima-tsumugi.

- Fading Craft: The Decline of Mud-Dyeing Artisans.

- Oshima-tsumugi Meets Global Fashion.

Authentic Black Dyed with

Techi Tree and Island Mud

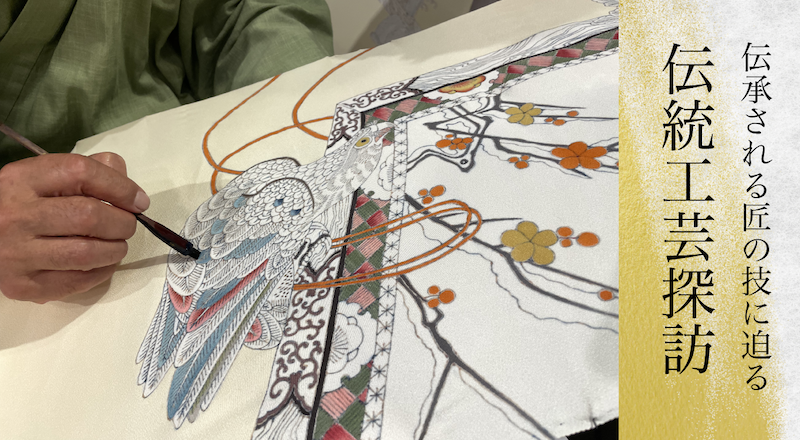

In addition to the intricate kasuri patterns and lightweight, supple texture, the rich, glossy black hue of authentic Amami Oshima-tsumugi is one of its most captivating features. This deep black is achieved through mud-dyeing, a technique unique to Amami. Local Techi trees are chipped and boiled to create a plant-based dye. Silk threads are immersed in this dye 70 to 80 times, with iron mordanting carried out in a mud field every 20 rounds to develop the signature color. At Kanai Kogei, located in Tatsugo Town—the heart of Oshima-tsumugi production—you’ll find vast dyeing vats, steamy cauldrons, and a beautiful mud field surrounded by subtropical trees. It is a setting that could only exist on Amami, where soil and tradition intertwine to produce textile magic.

A Traditional Technique That Requires Nearly

80 Cycles of Dyeing to Achieve the Ideal Shade

Kanai Kogei, founded in 1958, is a renowned mud dyeing (dorozome) studio on Amami Oshima that draws visitors from all over Japan seeking to experience this rare and authentic technique. The studio was established by Mr. Kanai at the age of 22 and continues to preserve the island’s unique tradition.

The dyeing process begins by immersing base threads and kasuri-patterned yarns in a rich brown liquid made from boiled techi tree (Symplocos lucida), a rose-family tree known locally as techi and more widely as sharinbai in Japanese. This natural extract serves as the first step in achieving the deep, lustrous black that defines authentic Oshima-tsumugi.

According to records in the ancient Shōsōin archives, reddish-brown kimono fabrics were once presented as tribute from southern regions. These are believed to have originated from Amami Oshima, dyed with the rich hues extracted from the island’s native techi tree (Symplocos lucida). This suggests that the history of textile dyeing on Amami Oshima spans more than 1,300 years, with techi long revered as a noble and ancestral dye.At Kanai Kogei, the dyeing process begins in a large iron cauldron where an astonishing 600 kilograms of techi wood chips are boiled at once to create the dye extract.

“The roots contain the highest concentration of tannins,” says Mr. Kanai. “In the past, people used to cut the roots with axes. About 40 years ago, a chipping machine was introduced, which made the process more efficient. While techi still grows wild on Amami, harvesting 600 kg is no easy task. We work with pulpwood contractors who chip techi for us when they come across it during their logging operations. Because freshness is key, the chips must be boiled within two weeks of processing.”

Mr. Kanai explains that after boiling the techi wood chips for two full days, the extract must be left to rest for about a week before it becomes a usable dye.When we visited the workshop, two seasoned artisans were hand-dyeing pre-resisted yarns in large brass-colored vats. These vats, stained over time by the reddish-brown dye, had taken on such a hue that one could mistake them for copper.

“Because we work with natural dyes, each batch behaves differently,” Mr. Kanai says.“Even if the dye isn’t strong at first, you can still achieve the same color by repeating the process 80 times or more. But overdyeing makes the threads thicker, which makes them difficult for the weavers to use. The ideal is to build up the color in about 70 to 80 rounds of dyeing, which results in the thread swelling by around 30 to 35 percent—that’s the sweet spot.”

The dyeing process begins with techi wood, rich in tannins, simmered and used to color the threads a reddish-brown.Slaked lime is added to balance the acidity, and artisans carefully adjust the amount with each round—up to 70 or 80 times—to achieve the ideal tone without thickening the yarn too much.

Fine-Grained Mud is

Key to Oshima’s Iconic Black

Once dyed about 20 times, the threads are taken to a nearby mud field.Here, the tannins in the techi dye react with the iron-rich mud, transforming the color into a deep, glossy black. This process is repeated four times—techi dyeing, then mud immersion—to create the signature black of Oshima Tsumugi.

Mr. Kanai, knee-deep in water, washes the threads rhythmically. At times, he strikes them against boards to spread the mud particles evenly.

One bundle can weigh up to 40 kilograms when wet—it’s a demanding yet essential step.

“The fineness of the mud is crucial,” he says.

“And having a mud field right next to our studio is rare, even in Amami.”

In true Amami tradition, dyeing must be done with nature—where the mud is, the artisans go.

“Unlike glossy black, the black created by mud-dyeing has a subdued depth, and depending on the angle, it can appear almost brown. After ten years, it gradually turns into a rich, dark brown. That’s the beauty of plant-based dyeing—the color shifts gently over time. When worn across generations, the fabric develops even more character. This is one of the quiet charms of Oshima Tsumugi.”

Expanding the Reach of Mud-Dyeing

Beyond Kimono

At Kanai Kogei, the craft of mud-dyeing is not limited to Oshima Tsumugi kimono. When traditional wear began to lose popularity and production declined, Mr. Kanai sought new ways to keep the tradition alive. Hoping to introduce mud-dyeing to a broader audience, he began sending dyed textiles to companies outside the kimono industry. His efforts paid off—apparel brands such as BEAMS and UNIQLO began to take notice.Today, the workshop handles orders from major fashion houses, with Mr. Kanai’s son, leading the apparel division. For over 40 years, Kanai Kogei has also welcomed the general public to experience mud-dyeing firsthand. Visitors from across Japan and abroad continue to find inspiration in the beauty of this age-old technique, forging new connections through the colors of Amami.

“When we started working with the apparel industry

and opened our mud-dyeing workshop to tourists 40 years ago,

some accused us of tarnishing the name of traditional craft,”

says Mr. Kanai.

“But in the end, it was often the companies

that clung solely to tradition

that couldn’t survive.”

Back when Kanai Kogei was founded,

there were around 60 mud-dyeing workshops in Tatsugo Town.

Today, only two or three remain.

It is precisely because the Kanai family

dared to step beyond the boundaries of kimono—

into apparel collaborations and hands-on experiences—

that they have been able to continue

their work with Oshima Tsumugi.

The production of authentic Amami Oshima Tsumugi

is a complex system of 38 separate processes,

each handled by a different specialist.

If even one workshop closes its doors,

the entire craft is at risk of disappearing.

Mr. Kanai also serves as a board member of the Amami Oshima Tsumugi Cooperative Association. Like many traditional craft industries across Japan, the aging of skilled artisans and the lack of successors is a serious challenge.

“It’s not just about continuing mud-dyeing. We need to think seriously—together with both public and private sectors—about how to pass down all of Amami’s cultural traditions to the next generation,” he says.

His calm tone carries a deep sense of responsibility and devotion to preserving the legacy of authentic Amami Oshima Tsumugi.

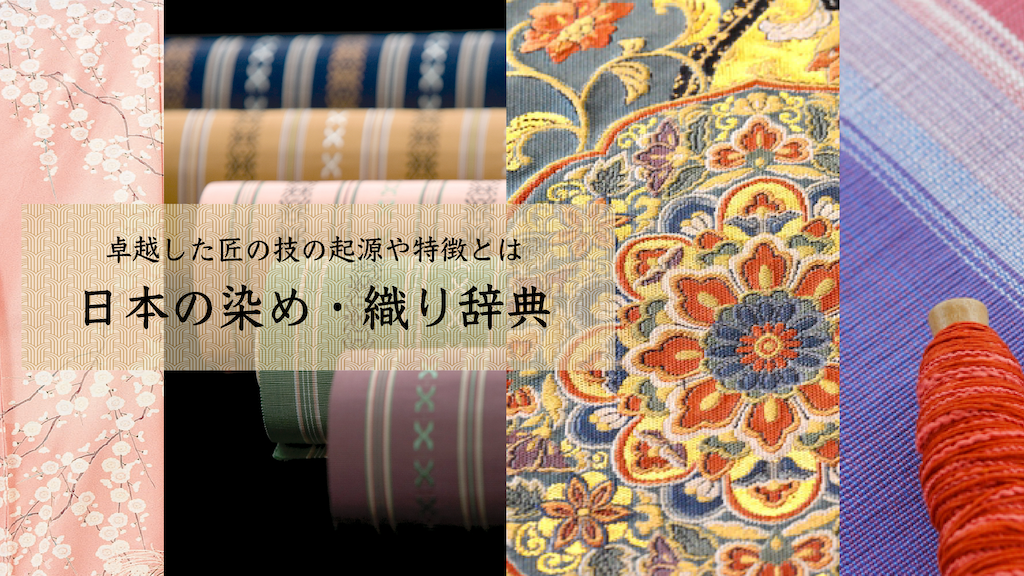

See Also : The Textile Encyclopedia | Amami Oshima-tsumugi (Kagoshima Prefecture)

____________________________________

Kanai Kogei

2205-1 Toguchi, Tatsugo-cho, Oshima-gun, Kagoshima Prefecture

TEL: +81-997-62-3428

Official Website>>

__________________________________

Text & Interview by Miki Shirasu