Draped in Grace

Designs Reflecting a Devotion to

Domestic Silk and Contemporary Sensibility

The whiteness of silk — a silence before it meets color. Based in Kyoto, Itoko is a renowned specialist in undyed silk fabric, dedicated to weaving the beauty of Japan using Matsuoka-hime, a rare, 100% domestically produced cocoon. We spoke with them to explore the profound aesthetic sensibility woven into their pristine white textiles.

In This Article:

・The history of Itoko and its philosophy as a specialist in shirojigake (white base fabric).

・The use of domestically produced silkworm cocoons, “Matsuoka Hime,” and sustainable silk production.

・Aesthetic sensibilities shaped by the relationship between silk and Nihonga (Japanese painting).

・Expansion into architecture and interior design (silk glass, silk shoji screens).

Itoko is one of Japan’s leading makers of shirojigake, or white base kimono fabric. Since its founding in 1931, the Kyoto-based company has developed more than 200 types of white fabric and over 3,000 unique pattern designs. Their fabrics have even been selected for use by the Imperial Household. With an unwavering commitment to 100% domestically produced silk, Itoko preserves the value of its brand by collaborating with master artisans in every field—sericulture, silk reeling, weaving, and dyeing. In this interview, we speak with Ms. Sachi Kitagawa, the third-generation president of Itoko, about the company’s dedication to homegrown silk, its approach to design, and new possibilities for silk textiles.

Preserving Kimono Culture

with a Commitment to 100% Domestic Silk

Silk textiles begin with the silkworm cocoon. To produce a full kimono ensemble—ranging from juban (under-kimono) to obi—approximately 10,000 cocoons are required. Cultivating that many silkworms demands around 230 square meters of mulberry fields and 330 kilograms of mulberry leaves. Sericulture was once a key driver of Japan’s modernization. In 1909, Japan became the world’s top exporter of raw silk. At its peak, there were some 2.2 million sericulture farms across the country. Today, that number has dwindled to just 180 due to falling demand. Although domestic raw silk now accounts for only 0.5% of all silk products distributed in Japan—leaving most producers reliant on imported threads—Itoko remains steadfast in its dedication to preserving “purely Japanese” silk, beginning with the cocoon.

In 1996, thanks to the tireless efforts of Ms. Kitagawa’s late father, Japan’s first fully integrated brand—from cocoon to raw silk to white silk fabric—was born: “Matsuoka Hime.” Rooted in the belief that kimono, as a cultural heritage of Japan, should be woven from threads nurtured in the country’s own natural environment, the initiative marked a major milestone in domestic silk production. Matsuoka Hime uses a premium silkworm variety originating from the Shōnai Domain in Yamagata Prefecture, known for its elasticity and exceptional luster. These silkworms are lovingly raised by dedicated sericulture farmers in Fukushima Prefecture. Ms. Kitagawa carries forward her father’s legacy, devoting herself to further refining Matsuoka Hime’s delicate, supple texture and ensuring its continued evolution.

“For me, preserving Japan’s high-quality silk cocoons also means preserving the kimono as a cultural legacy,” explained Ms. Kitagawa.

“Unfortunately, few people realize that most of the raw materials for kimono today are imported.That is why we are committed to keeping material production within Japan, even if only in a small way. To achieve that, we must protect sericulture farmers, support domestic silk-reeling, and ensure that those who weave kimono can continue their craft. If everything disappears, we can no longer create even ‘1’. But if ‘1’ still exists, I believe we can expand it to ‘2’ and ‘3’ in the future.

Jacquard Patterns Inspired by Japanese Painting —

The Signature of Itoko

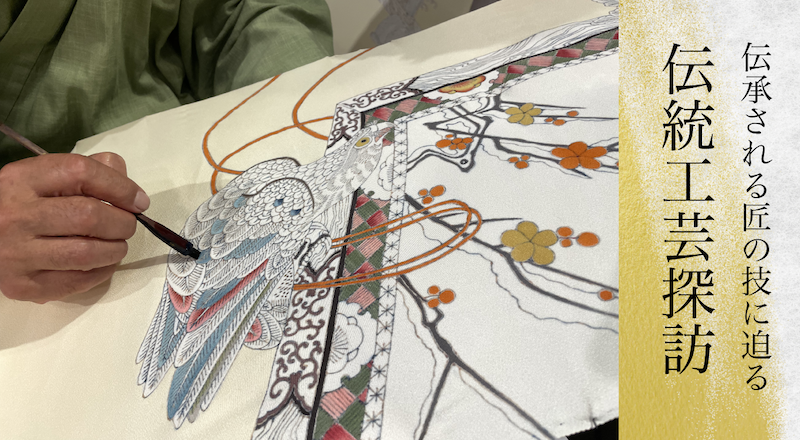

The founder, Mr. Kojiro Ito, was a Nihonga (Japanese-style) painter who went by the artist name “Kozan.” His aspiration was to weave the brushwork spirit of Nihonga into woven jacquard patterns. With that in mind, he established a business that manufactured and sold white silk fabrics incorporating his own hand-drawn patterns. What he valued most in his designs was the flowing movement of the brush tip— a uniquely Japanese painterly sensibility that continues to define Itoko’s aesthetic today.

Ms. Mariko Hirota, who currently heads the design department at Itoko, studied traditional Japanese painting throughout high school and university. Her fresh and vibrant sensibility has led to a series of hit designs, earning her recognition as a trendsetter within the company. Among her notable contributions is the innovative reinterpretation of Iromuji—traditionally considered semi-formal wear—into designs with a touch of Tsukesage-like elegance, expanding its potential across a wider range of occasions.

“We cherish the original design drawings stored in our archives, but we also encourage her to add a layer of modern creativity suited to today’s sensibilities. While most patterns are now created digitally using tools like Photoshop and Illustrator, we deliberately value the brushstrokes and subtle irregularities found in Nihonga (traditional Japanese painting), incorporating those nuances into our jacquard patterns. I believe it is precisely this foundation in Nihonga that allows our bold designs to still be distinctly ‘Itoko’ in spirit.”

A Woman’s Perspective on Kimono Comfort

The President Who Wears What She Creates

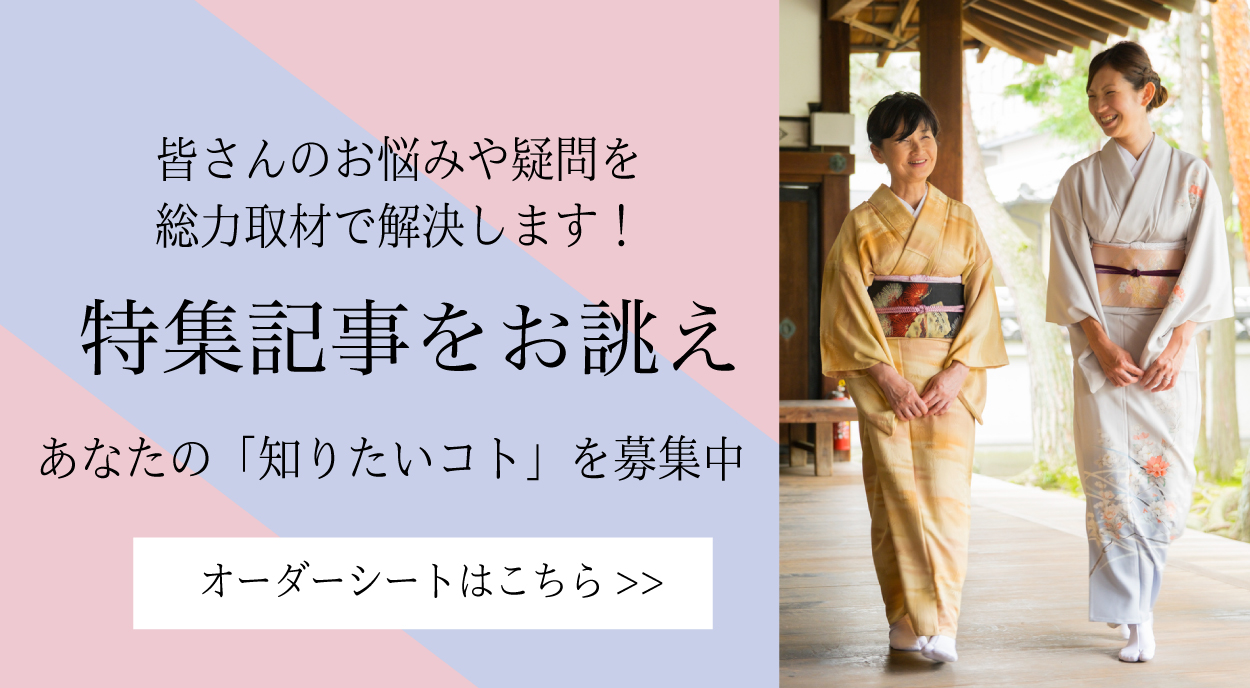

Ms. Kitagawa, the president of Itoko, also serves as a board member of the Kyoto Textile Wholesalers Association—the only woman among nearly 100 member companies.

“The kimono industry is still largely male-dominated, and Itoko, too, relies heavily on the experience and leadership of its male executives. That said, I believe my unique contribution as a woman lies in being able to wear the kimono myself and give honest, firsthand feedback. I might say things like, ‘This fabric feels too airy when I walk,’ or ‘It has a nice drape—maybe it’s suitable for a single-layer kimono,’ or even, ‘The weave feels a little loose.’ I share all of this directly with our production team. To ensure that our customers say, ‘As expected from Itoko,’ I personally try on each fabric—even if it means putting myself on the line”.

Bringing the Grace of Silk into Interiors

Blending Tradition and Innovation

As the market for traditional kimono shrinks, Itoko has taken a bold step by introducing silk textiles into interior design. One of their innovations is “silk glass,” a unique material combining silk with laminated glass for architectural applications. They have also developed lightweight resin-based products like “silk shoji(translucent sliding screens)” and “silk panels.” By blending the inherited craftsmanship of artisans with contemporary technology, Itoko is opening new possibilities for the future of silk.

“We hope to share the traditional beauty of Japan with people around the world by reimagining silk textiles—not only for kimono, but also as interior materials that enhance architectural spaces. Even those who do not wear kimono may come to appreciate the elegance of Japan’s finest silk, and feel a sense of pride in this cultural heritage.”

With silk at its core, Itoko continues to develop a wide range of innovative applications in collaboration with advanced technologies. From honoring Japan’s proud sericulture traditions to expressing the timeless grace of silk, their bold efforts are paving the way for a new generation—and introducing the spirit of Japan to the world.

See also: The Texile Encyclopedia | Tango-chirimen(Kyoto Prefecture)

_________________________________________

Itoko

448-2 Ryuchi-cho, Oike-dori Muromachi Higashi-iru, Nakagyo-ku, Kyoto,

Official Website>>

_________________________________________