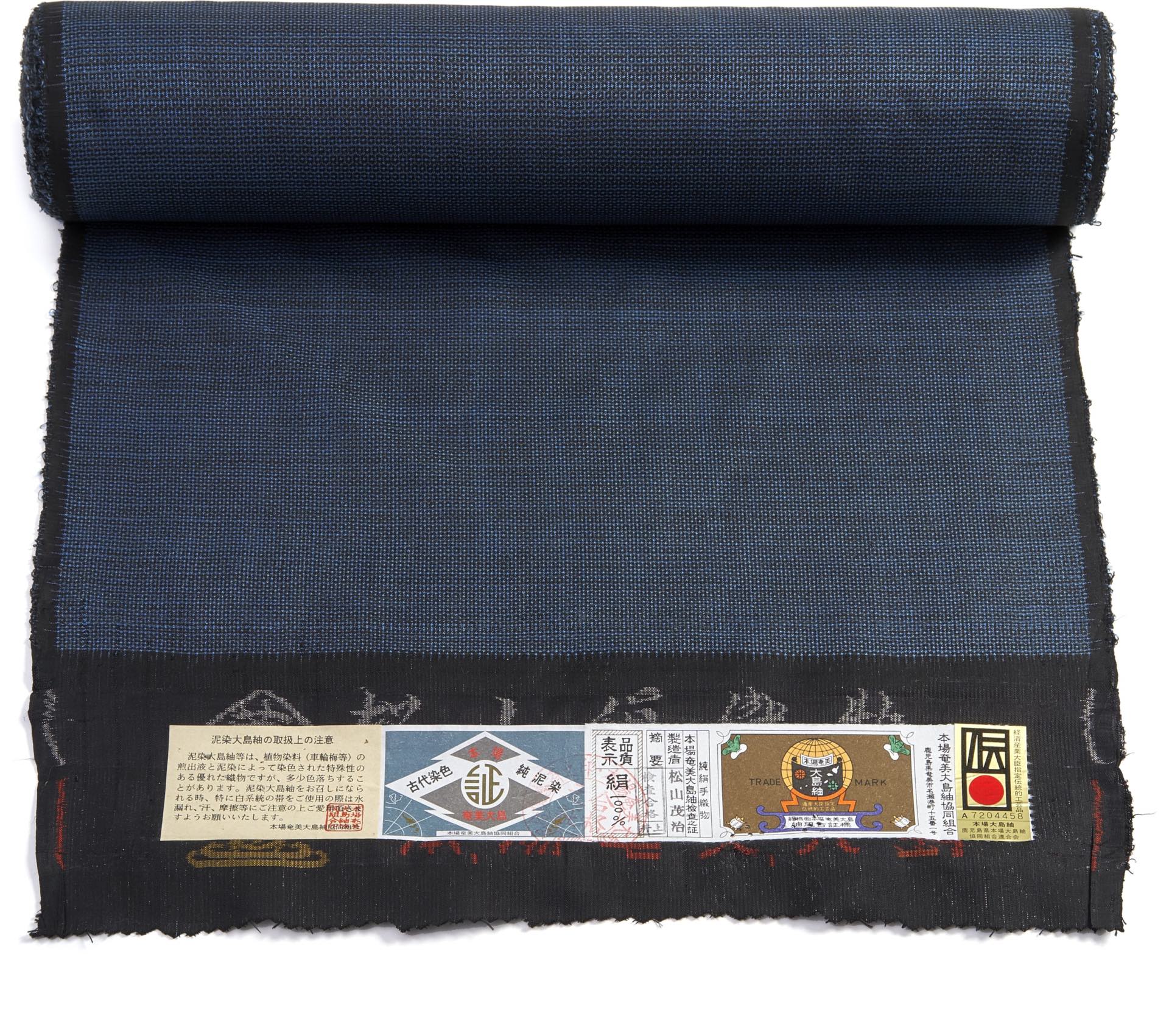

本場奄美大島紬

Pronunciation: Honba Amami-Oshima-tsumugi

Production Area: Amami Oshima Island, Kagoshima Prefecture

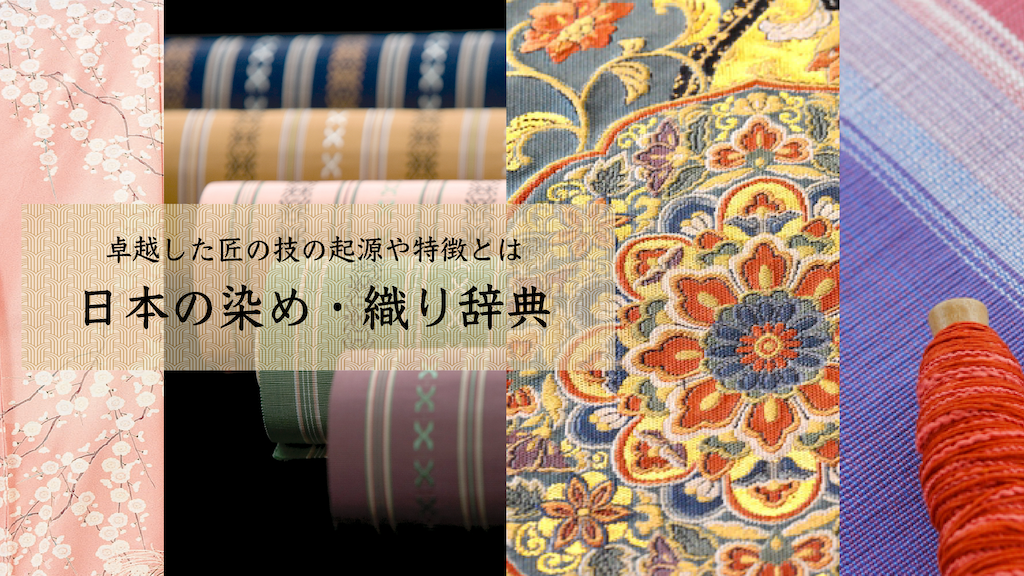

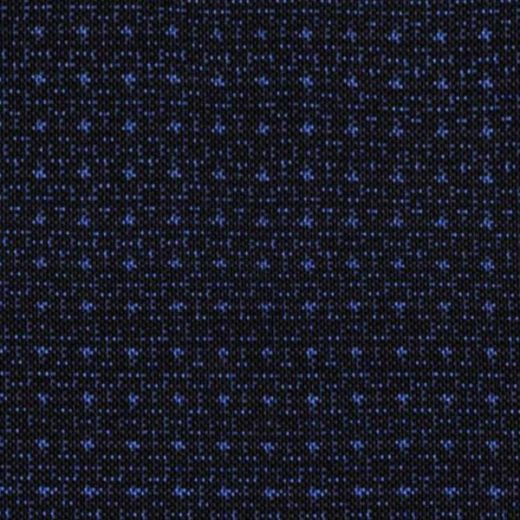

Oshima-tsumugi is regarded as one of the world’s three great textiles, alongside Gobelin tapestry and Persian carpets. Originating on Amami Oshima, this silk textile is known for its glossy, supple texture produced through more than 30 intricate processes, earning it the title “Queen of Kimono.” There are several dyeing variations: - Doro Oshima (Mud Oshima): Dyed with techi (Yeddo hawthorn) wood and mud, producing a distinctive dark brown-black ground. - Ai Oshima (Indigo Oshima): Woven with indigo-dyed threads. - Doro-ai Oshima (Mud-Indigo Oshima): A combination of mud dyeing and indigo dyeing. - Iro-doro Oshima (Colored Mud Oshima): Uses mud-dyed ground threads with kasuri (ikat) pattern threads applied by the traditional rubbing technique. - Iro Oshima (Colored Oshima): Both ground and kasuri threads are dyed with chemical dyes, resulting in a wide range of brilliant colors. - Chukan-shoku Oshima (Intermediate Color Oshima): Ground threads are left white, while pre-dyed colored threads create subtle mid-tone effects. A unique feature of Oshima-tsumugi is its “maruki” unit, which indicates the number of warp ikat threads. One maruki equals 80 warp kasuri threads. Common standards are 5-, 7-, 9-, and 12-maruki. The higher the maruki count, the more precise and intricate the alignment of warp and weft ikat patterns must be, making the textile more refined and valuable. Silk production on Amami dates back to the Nara period (8th century), and records in the Shosoin Repository of Todaiji Temple note offerings of tsumugi cloth. In 1720, commoners were forbidden from wearing tsumugi, reserving it as tribute to the Satsuma domain. From the 1870s, however, Oshima-tsumugi began to be produced as a commodity, and efficiency improved with the introduction of high looms.

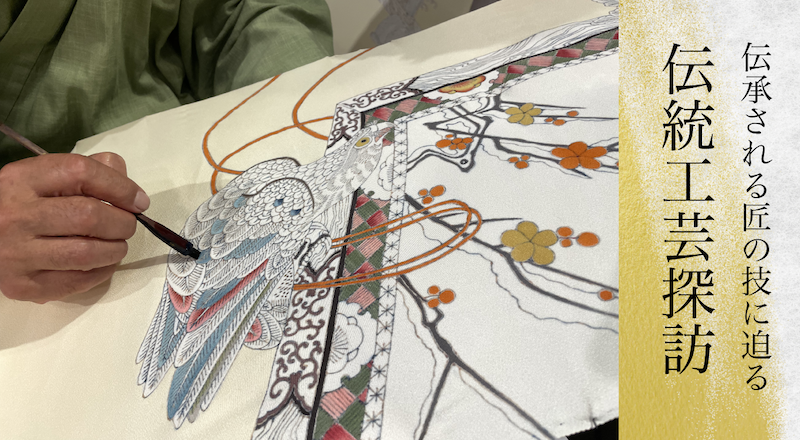

See Also: Traditional Craftsmanship vol.10 "Oshima-tsumugi"

Representative Patterns of Oshima-tsumugi

Tatsugo-gara (Tatsugo Pattern)

Created in the late Edo period when the Satsuma domain ordered artisans to devise a pattern unique to Amami. One designer was inspired by the sight of a golden habu snake glittering in the moonlight as it slithered across the fronds of a cycad plant. Villagers competed to interpret the snake’s back, the cycad leaves, and Amami’s lush natural scenery into abstract designs. First produced in Tatsugo Village, the motif was named “Tatsugo-gara.” Even today, it requires highly skilled weavers and remains a precious design.

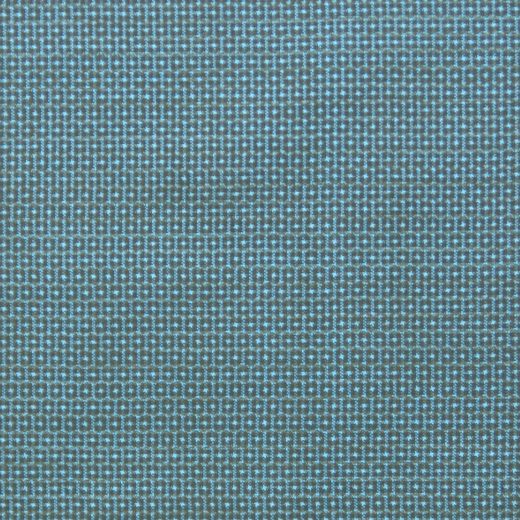

Akina-bara (Akina Basket Pattern)

“Bara” means bamboo basket in the Amami dialect. This motif originated in the coastal Akina district, inspired by bamboo household baskets called sanbara. Dyed with hawthorn and mud, the black ground and kasuri threads form a basket-like lattice with intersecting crosses. It employs the rare naga-gasuri (long ikat) technique, making it highly labor-intensive and rare today.

Saigo-gara (Saigo Pattern)

A bold design featuring cross-ikat within lattice squares, traditionally used for men’s kimono. Named after Saigo Takamori, the famous samurai leader, due to its strength and prestige. Competing villages created numerous variations, resulting in more than a dozen types of Saigo patterns.

Arima-gara (Arima Pattern)

Named after its creator. Other name-based motifs include Den’yu-gara and Mantaro-gara, reflecting the artisans who developed them.

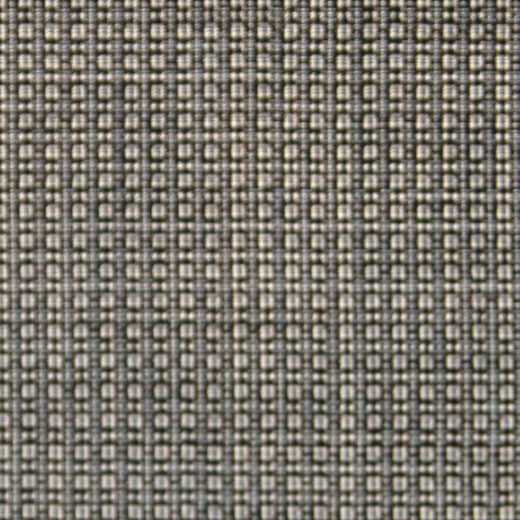

Kikko-gara (Tortoiseshell Pattern)

Based on the hexagonal pattern of a tortoise shell. Versions include 80-, 100-, 120-, 160-, 200-, and 220-kikko, referring to the number of hexagons across the width of a single bolt of fabric. The higher the count, the more kasuri threads are required, demanding exceptional skill and making the fabric exceedingly rare.

Photo courtesy of本場奄美大島紬協同組合